Understanding Caster Wheels

Caster wheels are essential components that facilitate movement for a wide range of objects, from furniture to industrial equipment. Predominantly used to improve mobility, they are mounted on the underside of various items enabling them to roll smoothly across surfaces. This ability not only enhances operational efficiency but also ensures that heavy, cumbersome items can be moved without exertion or potential damage to floors.

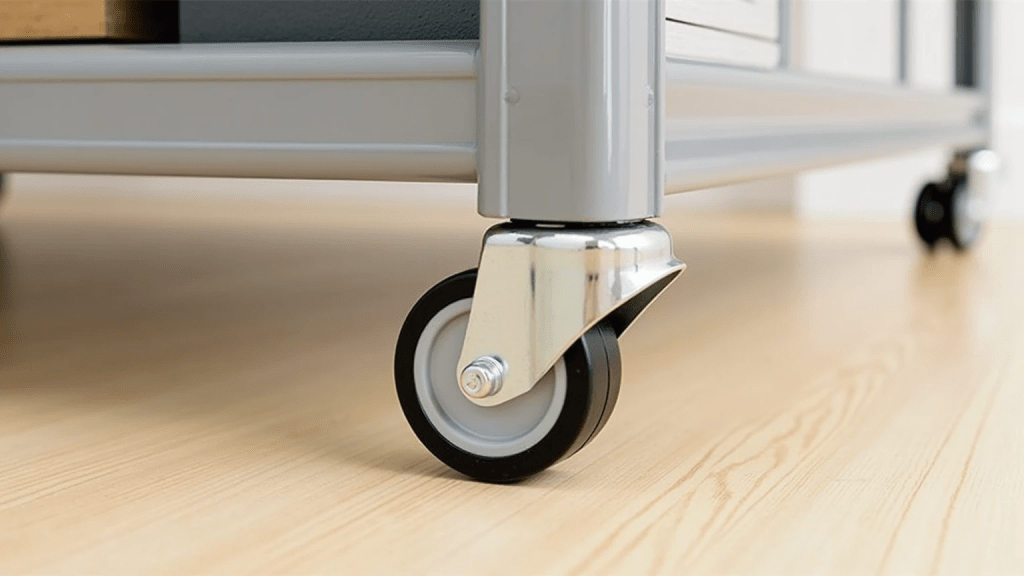

At the core of caster wheel functionality lie three main components: the wheel, the axle, and the mounting plate. The wheel, made from materials like rubber, polyurethane, or metal, allows for smooth gliding. The axle connects the wheel to the mounting plate, providing the rotation mechanism necessary for movement. The mounting plate securely attaches the entire caster assembly to the object, ensuring stability and load distribution across the wheelbase.

Caster wheels come in several types, each suited for different applications. Swivel casters, for instance, can rotate 360 degrees, providing exceptional maneuverability for objects that need to move in multiple directions, perfect for office chairs or hospital beds. Rigid casters, on the other hand, allow movement in a straight line and are ideal for steadier applications where directional changes are minimal, such as with warehouse carts. Locking casters provide added safety by allowing the wheel to be locked in place, making them suitable for environments where stability is a priority, like on slopes or uneven ground. Understanding these types and their specific uses helps ensure optimal performance and safety in various environments.

How to Replace Caster Wheels

Replacing caster wheels requires some essential tools and a bit of patience to ensure everything goes smoothly. You’ll need a wrench or pliers, a screwdriver if screws are involved, and suitable replacement caster wheels that match the specifications of the ones you’re replacing. Each tool serves a specific purpose: the wrench or pliers help in removing the old wheels, the screwdriver assists with loosening or tightening screws, and, of course, the new caster wheels are required for installation.

Here’s a step-by-step guide to replacing caster wheels:

- Preparation: Gather all your tools and new caster wheels. Ensure the area around the equipment or furniture is clear and that the object is on a stable surface to avoid accidents.

- Remove Old Wheels: Turn the furniture or equipment upside down carefully. If wheels are held by screws or nuts, use the screwdriver or wrench to remove them. If it’s a push-fit type, you might only need to pull them out; using pliers can provide additional grip if needed.

- Install New Wheels: Insert the new wheels into the appropriate slots or holes. Ensure they are properly aligned. For screw-in models, tighten the screws securely using a screwdriver. For push-fit types, make sure they click and fit snugly.

- Safety Check: Once installed, double-check to ensure the wheels are firmly attached and roll smoothly. Move the furniture back to its upright position and test the wheels for functionality.

It’s crucial to adhere to safety precautions throughout the process, such as wearing gloves to protect your hands and ensuring that the equipment or furniture is stable while you work on it. Regular maintenance and timely replacement of caster wheels can greatly enhance the longevity of your furniture or equipment’s mobility system.

Maintaining Caster Wheels

Proper maintenance is essential to prolong the lifespan of your caster wheels and ensure smooth operation. Regular maintenance includes activities such as cleaning, lubrication, and checking for wear and tear. Cleaning your caster wheels helps to remove debris that could cause blockage or reduce efficiency. Lubrication, usually with grease or oil, ensures that all moving parts function smoothly without unnecessary friction. Inspecting for wear and tear can help identify any defects such as cracks or chips, which are indicators that the wheel may soon fail. By undertaking these simple maintenance steps routinely, you can extend the life of your caster wheels, ensuring they remain reliable.

It’s important to be aware of the signs that indicate your caster wheels might need replacement. Common warning signals include unusual noises such as squeaking or grinding, difficulty in movement, or visible damage like cracks or deformations. These issues could signify underlying problems, such as worn-out bearings or structural weaknesses that might worsen if unaddressed. By recognizing these signs early, you can replace the wheels before failure, preventing potential damage to equipment or floors and safeguarding productivity. Keeping an eye out for these indicators helps maintain efficiency and safety in your workspace.

Choosing the Right Caster Wheels for Your Needs

Selecting the appropriate caster wheels involves evaluating several critical factors that influence their performance and longevity. First and foremost, consider the load capacity, which ensures the wheel can support the weight it needs to carry without risking damage or failure. Next, assess the wheel diameter; larger diameters usually provide better movement over uneven surfaces and distribute weight more evenly. Finally, the material of the caster wheels—such as rubber, polyurethane, or metal—affects durability and suitability for specific environments. Paying attention to these details will ensure the wheels perform optimally and last longer.

When choosing caster wheels for specialized flooring types, the right selection can significantly impact both mobility and floor preservation. For hardwood floors, soft-tread caster wheels made from materials like rubber or polyurethane are recommended, as they provide smooth navigation and reduce the risk of scratching. For carpets, hard-tread wheels are better suited since they can roll more easily without getting stuck. On tile floors, caster wheels with a non-marking material that absorbs shock and reduces noise are ideal. These tailored choices help maintain the integrity of the floors while ensuring effective movement.

FAQs about Caster Wheels

What are the benefits of using caster wheels?

Caster wheels enhance mobility by allowing for easy movement of furniture and equipment, which is particularly useful in crowded spaces. They also improve space efficiency by enabling objects to be stored closer together and moved as needed. According to industry experts, incorporating caster wheels can reduce manual handling injuries by 15%, making them invaluable for both commercial and home use in reducing strain and improving efficiency.

How do I determine the correct size of caster wheels?

Determining the correct size of caster wheels is crucial to ensure optimal functionality. When selecting the right size, consider the weight of the item the caster wheels will support, as well as the height and type of application. Typically, heavier objects require larger wheels for better support and smoother mobility. Additionally, the specific application should inform your choice; for example, office chairs might need smaller, softer wheels than industrial carts. Ensuring the wheels are appropriately sized to your application will facilitate better handling and longevity.

留下评论