Understanding Caster Wheels and Their Importance

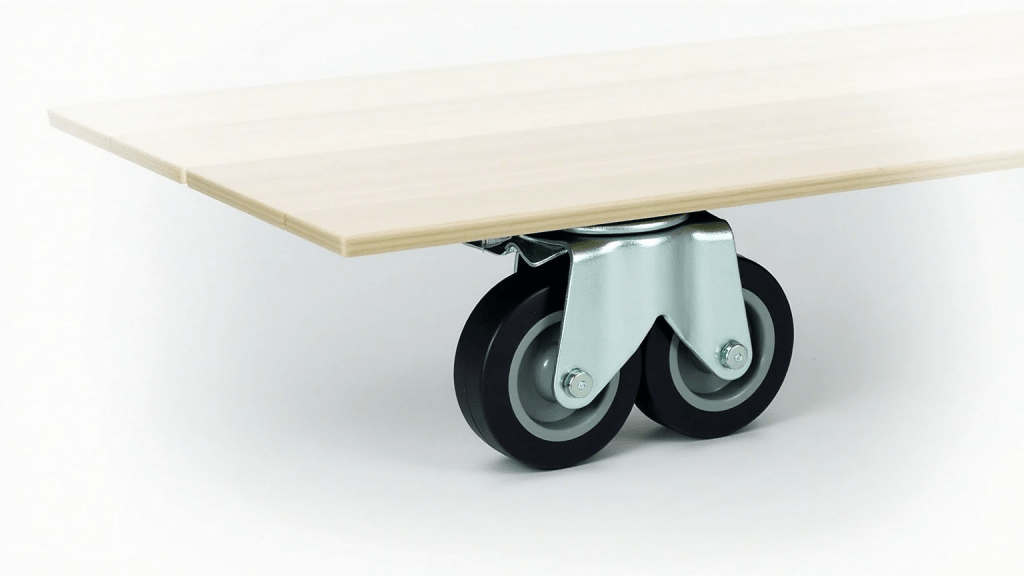

Caster wheels play a crucial role in facilitating the movement and mobility of various items, ranging from furniture to industrial equipment. Unlike regular wheels, casters are designed with a bracket or yoke that allows the wheel to swivel, thereby enabling multidirectional movement. This unique design makes casters an ideal choice for applications requiring ease of maneuverability. In contrast, a standard wheel merely rolls in a fixed direction without the swivel feature, which limits its flexibility. The inclusion of a swivel function in casters offers distinct mechanical advantages, such as enabling smooth navigation in tight spaces, much like a CVS 24-hour pharmacy enables accessibility around the clock, optimizing the efficiency of movement-heavy tasks.

Types of Caster Wheels

Caster wheels come in a variety of types, each designed for specific functions and environments. Broadly, caster wheels can be classified into two main categories: swivel casters and rigid casters. This segmentation highlights the different mechanical properties and functionalities that cater to diverse needs in industrial, commercial, and residential settings.

Swivel casters are noted for their exceptional maneuverability and flexibility, making them ideal for navigating tight spaces. These casters can rotate 360 degrees, which allows for easy directional changes and smooth movement across various surfaces. Their versatile nature finds applications in environments where frequent changes in direction are necessary, such as in hospital settings and furniture mobility.

Rigid casters, on the other hand, are vital for tasks requiring stability and straightforward motion. Unlike swivel casters, rigid casters maintain a fixed orientation, ensuring items move in a straight line. These characteristics make them indispensable for transporting heavy loads that need stable support, such as in material handling equipment and industrial machinery. The robust build and stability of rigid casters are essential in providing reliable mobility solutions for heavier applications.

Swivel Casters: The Versatile Choice

Swivel casters are engineered to pivot around a vertical axis, granting them exceptional flexibility. This unique design allows the wheels to rotate freely, enabling a full 360-degree movement. Such mechanics make swivel casters highly adaptable and versatile, allowing them to easily navigate tight spaces that rigid casters cannot manage. This feature is particularly beneficial in environments where directional changes are frequent and space is limited.

Swivel casters find widespread applications across various sectors, including furniture design, medical equipment, and warehouse operations. In the furniture industry, swivel casters enable easy movement of chairs and tables. In healthcare settings, they are essential in medical equipment like hospital beds and mobile diagnostic devices, facilitating effortless mobility. Furthermore, in warehouses, swivel casters enhance the efficiency of material handling by allowing carts and shelving units to be maneuvered with ease.

The primary advantage of using swivel casters lies in their ability to offer greater maneuverability compared to rigid casters. Their design significantly reduces the effort required to change direction, leading to less physical strain and fatigue for individuals operating equipment equipped with these casters. This ease of maneuvering not only saves time but also enhances safety and efficiency in workplaces where quick direction changes are commonplace.

Rigid Casters: Stability in Motion

Rigid casters are engineered for stability, featuring a fixed swivel mechanism that prevents any rotational movement. This structural design is particularly useful in scenarios where straight-line motion is critical, such as assembly lines and production processes. The rigidity ensures that carts and equipment move in a predetermined path, reducing the chances of deviation and enhancing operational efficiency.

These casters are best employed in environments where the need for directional stability outweighs maneuverability. For example, when transporting heavy loads in a straight line within a manufacturing plant, the use of rigid casters ensures consistent movement without the distractions of unwanted swiveling. The stability provided by rigid casters significantly improves load distribution, making them essential in material handling operations that demand robust support and reliable performance.

Choosing the Right Caster Wheel for Your Needs

When selecting caster wheels, you must consider key factors like load capacity, wheel material, and surface type. Load capacity is crucial because it determines the weight the wheels can handle without failure. For example, Caster Concepts offers high-capacity casters ranging from below 3,000 pounds to over 100,000 pounds, catering to various industrial needs. Additionally, wheel material affects durability and performance, with options like polyurethane for silent operations or steel for heavy-duty uses.

To aid in the selection process, understanding the weight capacities of different caster wheels is essential. Lightweight wheels might support up to 500 pounds, while industrial wheels, like those from Caster Concepts, can handle tens of thousands of pounds. This knowledge ensures you choose wheels that won’t collapse under pressure, maintaining safety and efficiency.

Material considerations also play a critical role in the selection of caster wheels. The durability and strength of materials like steel or rubber directly impact their longevity and cost. Steel wheels offer unparalleled strength for heavy loads, while rubber wheels are cost-effective for lighter applications. Balancing these attributes with budgetary constraints helps in making an informed decision.

Caster Wheel Maintenance and Safety

Proper maintenance and safety measures for caster wheels are essential to ensure longevity and prevent accidents. Regular cleaning and lubrication are mandatory to keep the wheels functioning smoothly, preventing dirt and debris buildup that can cause malfunction or wear. Cleaning should include removal of any entangled materials from the wheels and axles, and lubrication should be done with appropriate oils periodically to reduce friction.

To ensure safe usage, adhere to load limits specified by manufacturers to prevent overloading, which can lead to wheel failure. Proper installation is equally crucial; ensure wheels are securely attached to prevent dislodgement during use. Safety considerations also include checking for proper alignment and locking mechanisms where applicable.

Addressing common issues like noise, wobbling, or excessive wear can prevent further damage. Noise may result from insufficient lubrication or foreign particles that need removal. Wobbling often indicates misalignment or uneven surfaces, which require correction. Regular inspections can identify wear and mitigate risks through timely replacements. By following these tips, you can maintain efficiency and safety while utilizing caster wheels effectively.

Where to Find Quality Caster Wheels

When searching for quality caster wheels, it’s essential to consider reputable retailers that specialize in this industry. Leading distributors often offer a wide range of options that cater to various needs, ensuring you find the perfect match for your application. Well-known retailers provide assurance of product quality and durability, enhancing their reputation in the market.

Online shopping offers the convenience of browsing a myriad of options from the comfort of your home. It also allows for easy price comparisons, ensuring you get the best deal possible. By utilizing online platforms, you can access comprehensive product reviews and descriptions, aiding in a more informed purchase decision.

Local resources should not be overlooked; visiting local hardware stores or specialty shops provides the opportunity for personalized advice and immediate product availability. These venues often offer expertise that online platforms cannot, which can be especially valuable for specific or customized needs. By leveraging both online and local resources, you ensure a well-rounded search for high-quality caster wheels.

FAQ Section

What are caster wheels, and how do they work?

Caster wheels are a type of wheel designed with a bracket or yoke that allows the wheel to swivel, enabling multidirectional movement. This design facilitates smooth navigation and ease of movement for various items.

What is the difference between swivel and rigid casters?

Swivel casters are designed to rotate 360 degrees, providing excellent maneuverability in tight spaces, while rigid casters maintain a fixed orientation to ensure straight-line motion and stability for heavy loads.

How do I choose the right caster wheel for my needs?

Consider factors like load capacity, wheel material, and surface type. Ensure that the caster wheel can handle the weight it will support and is made from materials suited for your specific application.

What regular maintenance do caster wheels require?

Caster wheels require regular cleaning and lubrication to prevent dirt buildup, malfunction, and wear. Adhering to load limits, ensuring proper installation, and addressing issues like noise or wobbling are also crucial for maintenance.

Where can I buy quality caster wheels?

You can purchase quality caster wheels from reputable online retailers or local hardware stores specializing in these products. Both channels offer a range of options to meet specific needs and preferences.

留下评论