Understanding Digital Calipers: The Basics

Digital calipers are precise measuring tools that utilize electronic displays to show measurements in millimeters or inches, thereby enhancing both readability and accuracy. These versatile instruments, often found in manufacturing and engineering settings, offer users a seamless way to obtain exact measurements without the strains associated with manual readings. In terms of advantages, digital calipers surpass traditional measuring tools with their improved accuracy, significantly minimizing user error. One of the notable benefits is their ability to switch between measurement units easily, providing convenience for users needing flexibility. This advantage is particularly beneficial in environments where precision and efficiency are paramount, such as in quality control and detailed craftsmanship. The inclusion of features like zero setting at any position and automatic shut-off highlights the modern convenience offered by these measuring tools electronic.

Key Features of Digital Calipers

Digital calipers are prized for their accuracy and precision, crucial for precise measurements in various industries. Many modern digital calipers feature a measurement accuracy of +/- 0.02 mm, which ensures high precision even in demanding applications. This level of accuracy minimizes user errors and enhances the reliability of measurements, which is essential for tasks requiring extreme precision.

The intuitive design of digital calipers makes them user-friendly, catering to both professionals and beginners. Features such as large LCD screens enhance readability, allowing measurements to be quickly and easily read. Automatic shut-off functions help conserve battery life, and intuitive buttons ensure straightforward operation, which is particularly beneficial for those new to using digital measuring tools.

Furthermore, the durability and build quality of digital calipers are critical features that ensure long-term usability. Many digital calipers are constructed with materials like stainless steel, offering resistance to wear and corrosion. This robustness is vital when the tools are used in harsh environments, such as workshops or manufacturing plants where they are exposed to tough working conditions. The sturdy construction not only extends the lifespan of the caliper but also maintains its precision over time, providing a reliable measuring tool for various applications.

With these features, digital calipers are an essential component in the toolbox of anyone who requires exact measurements, offering advantages over many traditional and less sophisticated alternatives.

Types of Digital Calipers Available

Digital calipers come in several types, each offering unique features suited for different measuring needs. Among these, electronic digital calipers stand out for their advanced features, such as data output capabilities and the ability to store measurements digitally. These high-tech measuring tools often include functionalities like measurement conversion and data transfer ports, which enhance their versatility and ease of use in professional settings.

Vernier calipers, while traditionally analog, have seen modern adaptations with digital readouts. These digital vernier calipers combine the reliability of traditional measurement methods with the convenience of a digital display, offering precise readings without the parallax error associated with analog dials. This hybrid approach caters to users who appreciate the tactile feedback of manual calipers but require the precision and speed of digital technology.

Dial calipers provide another hybrid option, featuring both a traditional dial and quick digital readings. Though less common than their electronic counterparts, dial calipers are favored for their straightforward design and ability to offer a double-check mechanism through their analog and digital functions. This makes them particularly useful in scenarios where both digital and non-digital readings are desired, despite their reduced prevalence in modern industrial applications.

Using Digital Calipers Effectively

To use digital calipers effectively, it is crucial to employ precise techniques for accurate measurements. Proper placement of the caliper’s jaws on the object ensures direct reading and avoids errors such as parallax. Always ensure that the caliper is zeroed before taking measurements to establish a baseline and achieve accurate results. Zeroing involves closing the jaws and pressing the zero button to reset the display.

Routine zeroing and calibration are essential for maintaining the measurement accuracy of your digital calipers. Calibration checks should be part of regular usage to account for any wear or slight misalignments that can occur over time. Some digital calipers will come with manufacturer instructions for recalibration and it is important to follow these or consult a professional if needed.

Maintenance and proper care of digital calipers also play an important role in their effective use. Regular cleaning to remove dust and debris, along with storing the tool in a protective case, helps prevent damage. Avoid exposing your calipers to extreme temperatures or moisture, which can affect their sensitive electronics. This careful handling ensures the longevity and reliability of these monitoring tools.

Applications of Digital Calipers

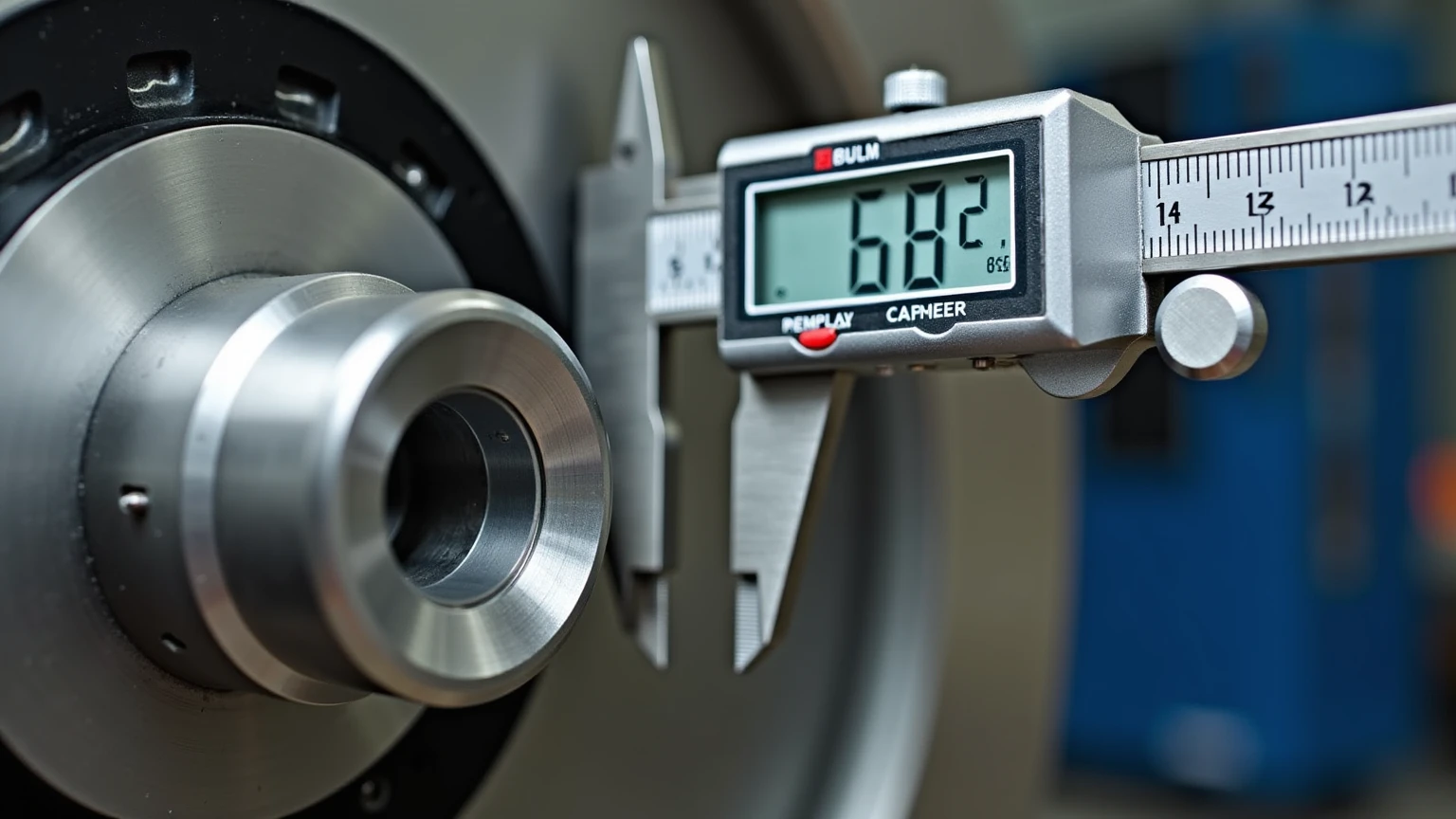

Digital calipers play a crucial role in engineering and manufacturing by ensuring precision in component fit and assembly. These tools are indispensable for checking tolerances and dimensions, which are vital for the assembly of mechanical parts. For example, when fitting parts to an engine or assembling electronic components, accuracy within a fraction of a millimeter can be the difference between success and failure.

In woodworking and DIY projects, digital calipers are just as valuable. Accurate measurements lead to better craftsmanship and reduced material waste. For a woodworker, precision in cutting and fitting can significantly impact the overall quality of the finished product. The use of digital depth gauges calipers helps avoid errors common with traditional measuring tools by providing fast and exact readings essential for achieving perfect joins and smooth finishes.

In the automotive repair industry, digital calipers are indispensable tools for technicians. They allow for precise measurement of parts and components, enhancing repair accuracy. For instance, during brake servicing, technicians can assess the wear on brake discs or pads with measurable precision thanks to these tools. This precision ensures that the components fit perfectly, reducing the risk of failures and enhancing the overall safety and performance of the vehicle.

Choosing the Right Digital Caliper

When selecting a digital caliper, it’s crucial to consider several key features that impact accuracy and usability. Begin by assessing the measurement range, which should accommodate the dimensions you frequently measure. Display quality is essential as well; a clear, backlit display can enhance readability, especially under varied lighting conditions. Battery life and the inclusion of an auto-off feature are also significant, as these features help conserve power and ensure consistent performance.

Additionally, consider top brands based on user experiences and industry reviews. For example, Mitutoyo is often praised for its superior power management and reliability, while iGaging’s models are noted for their absolute measurement capabilities and affordable price point. Consulting customer feedback can provide invaluable insights into which models consistently meet user expectations, thereby guiding you towards a purchase that aligns with your needs.

Common Misconceptions About Digital Calipers

Many believe that digital calipers are always superior to traditional ones, yet there are situations where traditional calipers may be more suitable. For example, tasks requiring simple measurement where precision beyond hundredths is unnecessary might not benefit significantly from digital readouts. Furthermore, traditional calipers don’t depend on batteries, making them more practical in some environments.

There is also confusion between accuracy and precision when it comes to digital calipers. Precision refers to the caliper’s ability to consistently reproduce a measurement, while accuracy is about how close a measurement is to the true dimension. Although digital calipers provide precise readouts, regular calibration is essential to ensure their measurements are accurate. Calibration helps mitigate errors caused by wear and environmental factors, ensuring the tool’s reliability over time.

FAQ

What are digital calipers primarily used for?

Digital calipers are primarily used for taking precise measurements in engineering, manufacturing, woodworking, and automotive repair. They are essential for determining component fit, checking tolerances, and ensuring precision in various technical applications.

How do digital calipers differ from traditional calipers?

Digital calipers use electronic displays to provide precise readings, making them generally more accurate than traditional calipers. They offer features such as measurement conversion, easy zeroing, and data output capabilities, unlike most traditional calipers.

What should I consider when buying a digital caliper?

When purchasing a digital caliper, consider its measurement range, display quality, battery life, and additional features like auto-off function. Checking customer reviews and brand reliability is also essential to ensure you select a suitable model for your needs.

How can I maintain my digital caliper for longevity?

Maintain your digital caliper by regularly cleaning it, storing it in a protective case, and avoiding exposure to extreme temperatures and moisture. Perform routine zeroing and calibration checks to ensure ongoing accuracy.

留下评论