What are Dielines in Packaging?

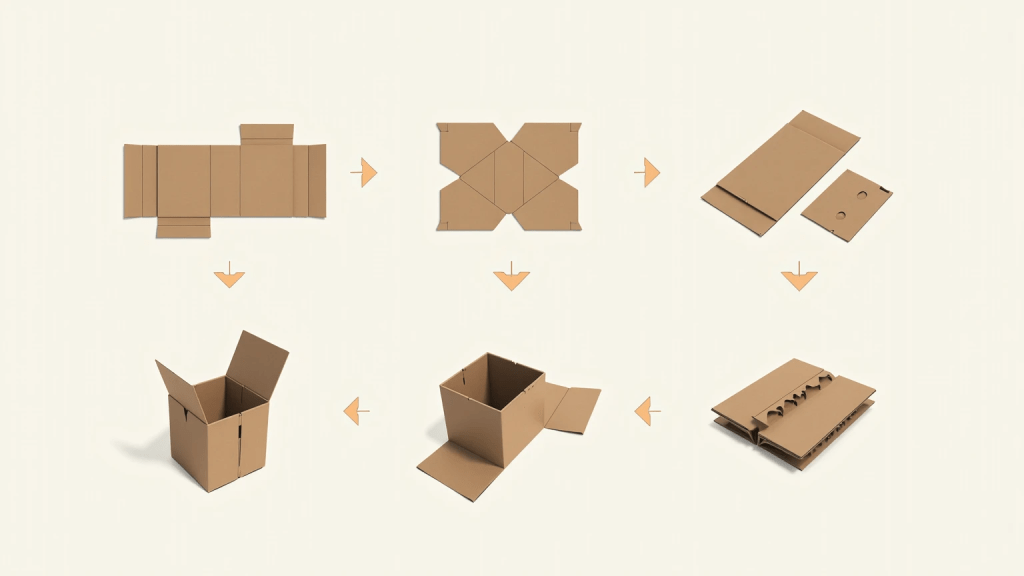

Dielines serve as essential guides in packaging design, playing a crucial role in how a printed piece will appear when cut and folded. They act as a blueprint for manufacturers, detailing the layout of a package in its flat form. By serving as a reference for all visual elements, dielines ensure that the final product matches the intended design.

Understanding dielines is vital because they indicate where cuts, scores, and folds will occur during the production process. These guides help maintain the structural integrity of the packaging, ensuring that it assembles correctly and functions as intended. Without accurate dielines, the packaging might not fit together properly, leading to potential design and production issues.

Key components of a dieline include dimensions, trim lines, bleed areas, and fold lines. Each element communicates specific design specifications to printers, guiding where to cut and fold the material. For instance, trim lines show where the cutting will occur, and bleed areas extend beyond the trim line to prevent white edges in the final product. Collectively, these elements ensure the packaging design is executed with precision.

Importance of Dielines in Packaging Design

Dielines play a critical role in the production of packaging by minimizing errors and ensuring that the final product aligns with the designer’s vision. As blueprints for packaging, they provide vital guidance for cutting, folding, and assembling printed materials. This accuracy prevents costly mistakes, such as misalignment or incorrect fitting, which can derail an entire production batch. By offering a clear representation of how a design will look when assembled, dielines help maintain the integrity and functionality of the packaging design.

Their importance extends to error detection and proofing processes. Designers and manufacturers can review dielines to identify and rectify potential errors before printing. This foresight saves both time and resources by preventing the expensive need for re-prints and corrections after the fact. It allows for efficient collaboration between all stakeholders involved in the design and production process, ensuring that any issues are addressed well in advance. As a result, dielines are indispensable tools in achieving seamless and successful packaging production.

How to Create an Effective Dieline

Creating an effective dieline requires using specialized software, such as Adobe Illustrator or ArtiosCAD, which simplifies the design process and ensures precision. These tools allow designers to construct accurate templates that act as blueprints for the final packaging. By leveraging the advanced capabilities of these programs, designers can easily create vector files that communicate every cut, fold, and alignment necessary for production.

In creating dielines, incorporating specific markers is crucial for maintaining production accuracy. Essential markers include registration marks and fold indicators, which guide the printing and cutting processes. Registration marks help ensure the alignment of colors in multi-color prints, while fold indicators show where the material should be creased, ensuring that the final product assembles correctly. These markers not only streamline production but also minimize errors, contributing to an efficient and effective manufacturing process.

Common Mistakes in Dieline Design

Identifying errors in dieline design is crucial to avoid production issues. Common mistakes include incorrect measurements, missing bleed areas, and misaligned graphics. These errors can lead to costly delays and unsatisfactory packaging results. For instance, without the correct bleed area, graphics may print incorrectly, resulting in crucial parts of the design being cut off. Additionally, precise dieline measurements are essential to ensure a perfect fit for the product, avoiding the risk of packaging failure during shipping.

To improve dieline accuracy, several recommendations can be followed. First, implement thorough proofing protocols, such as cross-verification against project specifications to ensure all design elements are correctly positioned. Second, utilizing templates from experienced designers can serve as a reliable foundation, minimizing guesswork in the design process and ensuring the final output meets professional standards. By adhering to these strategies, you can significantly enhance the precision and functionality of your packaging design.

The Dieline Process in Packaging Production

The dieline process in packaging production is a collaborative effort that requires clear communication between designers and manufacturers. This cooperation ensures that the design specifications are accurately translated into a die-cut format, pivotal for the final packaging integrity. Any misalignment or misunderstanding during this stage can result in costly errors and delays. Hence, both parties must work together closely to address any issues quickly and maintain seamless coordination throughout the project.

Quality control plays a crucial role in ensuring that die-cutting aligns precisely with the dieline specifications. This alignment is essential as it determines the overall quality and functionality of the packaging, influencing customer satisfaction and brand perception. Rigorous quality control measures, such as thorough inspection protocols and advanced technological tools, are necessary to detect and rectify any discrepancies. The primary goal is to uphold the accuracy of the dieline design and guarantee that the finished packaging meets all intended standards without compromise.

Future Trends in Dieline Usage

The landscape of dieline usage in packaging is evolving with a growing emphasis on sustainability. With eco-friendly materials and designs, companies are now focusing on reducing waste in packaging production. By incorporating recyclable materials and optimizing the dieline process to use the least amount of material possible, businesses can significantly lower their environmental impact. As consumers become more environmentally conscious, the demand for sustainable packaging solutions continues to rise, pushing companies to innovate in this area.

In addition to sustainability, technological advancements in dieline design are setting the stage for the future of packaging. The integration of automation and AI-driven tools in dieline creation is expected to enhance accuracy and efficiency. These technologies streamline the design process, reducing the risk of human error and accelerating production timelines. As such, adopting advanced software and tools will likely become indispensable for companies aiming to stay competitive in the ever-evolving packaging industry.

FAQs

What is a dieline in packaging?

A dieline is a template used in the packaging and printing industry to ensure that a design is correctly laid out for cutting and folding. It helps in the precise placement of cuts, folds, and scores.

Why are dielines important in packaging design?

Dielines are crucial because they help in minimizing errors, ensuring that the final product aligns with the design, and preventing costly production mistakes.

How are dielines created?

Dielines are created using specialized design software like Adobe Illustrator, incorporating all necessary markers and specifications for accurate production.

What are some common mistakes in dieline design?

Common mistakes include incorrect measurements, missing bleed areas, and misaligned graphics, which can lead to production errors and unsatisfactory results.

How are dielines evolving in the packaging industry?

Dielines are becoming more focused on sustainability and technological advancements, incorporating eco-friendly materials and automation tools to improve efficiency.

留下评论