What is a Banding Tool and Its Importance in Packaging?

A banding tool is a vital device used to securely bundle products together using bands made of plastic, metal, or paper. These tools are indispensable in ensuring that products remain intact during transportation and storage, thereby safeguarding product integrity. By applying tension and sealing bands around items, banding tools play a critical role in the packaging process, particularly for industries requiring reliable product stability.

Banding tools find diverse applications across various sectors, including food and beverage, construction, and retail. For instance, in the logistics industry, they help stabilize products on pallets to prevent movement during transit, reducing the risk of damage. In construction, these tools are employed to bundle materials like pipes and timber, highlighting their adaptability to different packaging needs and enhancing operational efficiency by minimizing waste.

Moreover, banding tools are crucial in branding and aesthetics by providing a neat and tidy packaging finish. They also contribute to reducing packaging costs and improving supply chain logistics by streamlining the bundling process. This ensures a reduction in material usage and labor costs while improving overall packaging efficiency, making them an essential component of modern packaging strategies.

Key Features to Consider When Choosing the Best Banding Tools for Packaging

When selecting banding tools, material compatibility is a crucial aspect to consider. Banding tools are generally designed for plastic or metal straps, each offering distinct advantages. Metal straps provide robust support for heavier loads, making them ideal for industries like construction and logistics. In contrast, plastic straps, notably polyester and polypropylene, are preferred in the food and beverage sector for their flexibility and cost-effectiveness.

Another vital feature to consider is the strap width and thickness. These factors significantly affect the tool’s suitability for specific packaging needs. For example, heavy machinery requires wider and thicker straps to ensure secure bundling. In retail, where packaging requirements might vary, having a range of strap dimensions available is essential to accommodate various product sizes and weights effectively.

Understanding the difference between manual and automated banding tools is important for productivity. Automated tools are highly efficient, enhancing productivity, particularly in large-scale operations where speed is critical. Statistical data indicates a 30% increase in productivity when using automated banding tools in such environments. Meanwhile, manual tools are more effective where precision is needed in smaller operations that handle irregular or delicate items.

Lastly, ease of use and ergonomics in banding tools are fundamental for reducing worker fatigue and increasing efficiency. Tools with ergonomic designs allow users to operate more comfortably over extended periods, minimizing the physical strain associated with frequent banding tasks. Enhancing packaging efficiency, these designs contribute to safer and more productive work environments.

Types of Banding Tools and Their Unique Features

When considering banding tools for packaging, there are several types to choose from, each with distinct advantages and applications. Manual banding tools are the simplest, yet they offer a straightforward mechanism that makes them ideal for low-volume applications. These tools are particularly cost-effective, making them a popular choice for smaller businesses that don’t require specialized machines for their packaging needs.

Pneumatic banding tools rely on compressed air to operate, which greatly enhances their efficiency in high-volume tasks. Many industry players opt for these tools because they significantly speed up the packaging process in busy environments. Their power source enables consistent tension and sealing, crucial for maintaining package integrity.

Battery-powered banding tools stand out for their portability and ease of use, making them perfect for on-the-go applications across various settings. They eliminate the need for cumbersome cables or air hoses, offering mobility without sacrificing effectiveness. This flexibility is particularly beneficial for businesses that require banding in multiple locations or under constraints where power sources may be limited.

Meanwhile, automated banding machines take user intervention to the next level by optimizing entire production lines. These machines improve consistency in packaging, reduce labor costs, and increase throughput. For instance, advanced manufacturing facilities often use these machines to ensure seamless operations, allowing workers to focus on more value-added tasks within the production process. Automated systems can be customized to handle diverse products, further enhancing their appeal in busy industrial settings.

How to Maintain Your Banding Tools for Optimal Performance

To ensure the optimal performance of your banding tools, regular cleaning is crucial. Removing dirt and debris frequently prevents these elements from impairing the tools’ functionality. Tool manufacturers often recommend using a soft, dry brush or cloth to gently clean the surfaces of the tools, as well as the moving parts to prevent any obstruction that could lead to malfunction.

Periodic inspections for wear and tear are equally important in maintaining banding tools. Conducting regular maintenance checks helps in identifying any signs of damage early on, thus preventing costly downtime. According to industry standards, it is advisable to thoroughly inspect tools every few months, checking for loose parts or any other signs of wear that could compromise performance.

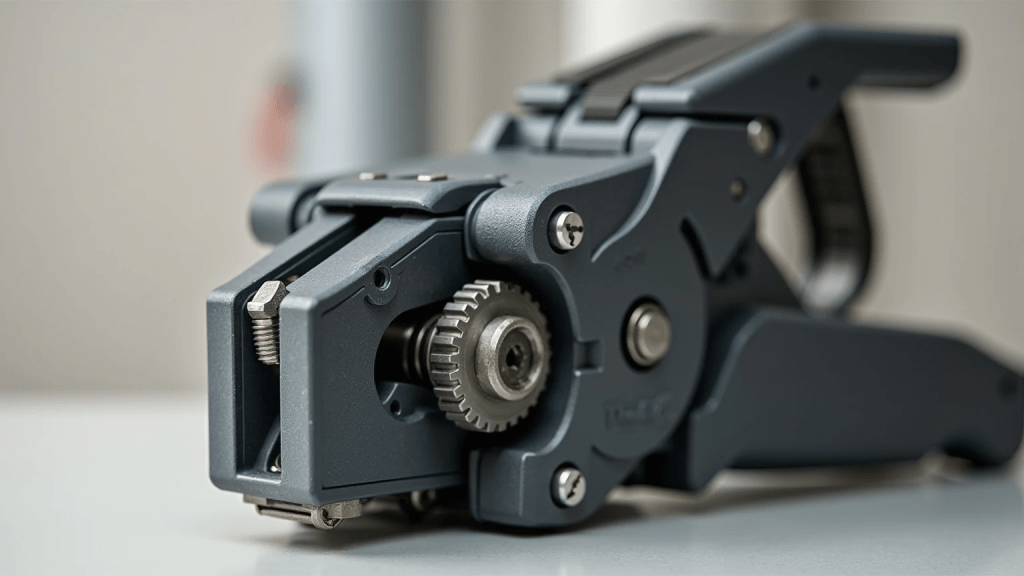

Lubrication and parts replacement are vital for prolonging the life of banding tools. Components such as gears and handles should be lubricated regularly to reduce friction and wear. It’s important to use the right type of lubricant for the specific tool to ensure efficacy and avoid damage. Regularly assess parts that frequently endure stress and replace them as needed to keep the tools functioning at their best. Adopting these practices not only enhances performance but also extends the longevity of the tools.

Understanding the Cost and Investment in Quality Banding Tools

The cost of banding tools varies significantly depending on the type and sophistication of the equipment. For instance, manual banding tools are typically more affordable, with prices ranging from $30 to $150, while pneumatic and automated options can start from $500 and reach upwards of $3000, according to industry data. Understanding these price brackets is crucial for businesses planning their budget allocation and selecting the right tools that align with their operational scale and needs.

Conducting a cost vs. value analysis underscores the long-term savings potential of quality banding tools. Although initial investments might be higher, superior tools often lead to better durability and efficiency, thereby reducing maintenance costs and operational downtimes. For example, a business that opts for high-grade automated banders can expect a substantial return on investment (ROI) as they streamline packaging processes and boost productivity, ultimately leading to cost savings in labor and time.

To make informed purchasing decisions, it’s essential to consider the total cost of ownership of banding tools. This includes not just the purchase price but also factors like maintenance, durability, and operational efficiency. Evaluating these aspects holistically helps businesses choose tools that offer the best long-term value and performance, ensuring that the costs associated with downtime and frequent repairs are minimized.

FAQs About Banding Tools

Understanding the difference between banding and strapping is crucial for selecting the right tool for your needs. Banding typically involves using a flat band to secure items for storage or shipment, often seen in packaging industries. Strapping, on the other hand, usually involves the use of a strap or belt to hold items together tightly, such as in bundling construction materials. For example, banding is ideal for securing boxes, while strapping might be used for heavier, irregular loads.

Using a banding strapping tool effectively involves a few key steps. First, select the right tool and band for your specific application. Then, thread the band through the tool and around the items to be secured. Tighten the band to ensure a snug fit, and use appropriate locking mechanisms to maintain tension. Practicing these steps can help beginners ensure they’re applying bands correctly and efficiently.

Routine maintenance is vital to keep your banding tools in prime condition. Regularly check for wear and tear, lubricate moving parts, and replace any worn components. Ensuring your tools are well-maintained not only extends their lifespan but also improves their performance and efficiency.

留下评论