Introduction to Lift Tables for Home and Industrial Use

Lift tables are versatile devices engineered to safely elevate, lower, and position workloads. Predominantly used in both home and industrial environments, their primary purpose is to facilitate the handling of goods by adjusting the height to a comfortable working level. This enhances safety, improves ergonomics, and boosts productivity in various settings.

Key Benefits of Lift Tables in the Workplace

Lift tables significantly enhance workplace ergonomics and safety by minimizing the physical strain on workers. By elevating heavy loads to a comfortable height, these tables reduce the need for bending and reaching, which are common causes of musculoskeletal injuries. According to the U.S. Occupational Safety and Health Administration (OSHA), businesses can decrease ergonomic-related injuries by up to 40% when implementing proper lifting equipment. These statistics underline the critical role of lift tables in promoting a safer working environment.

Moreover, lift tables considerably boost productivity and efficiency by streamlining loading and unloading processes. They allow workers to handle more materials with less fatigue, thus increasing the speed and efficiency of operations. A study conducted by the Material Handling Industry of America (MHIA) found that industries utilizing ergonomic equipment like lift tables saw productivity improvements ranging from 15% to 25%. This enhancement allows businesses to achieve faster turnaround times and improve workflow.

Lift tables offer remarkable versatility across diverse applications, making them invaluable in various settings. In warehouses, these tables facilitate the movement and placement of goods, significantly easing the restocking processes. In healthcare environments, lift tables assist in the safe handling of medical equipment and supplies, ensuring both patient and worker safety. Additionally, in retail settings, they enable smoother stocking and inventory management, reducing the likelihood of injuries during product handling. For instance, in a busy CVS pharmacy, lift tables can help pharmacists efficiently manage stock and enhance customer service by maintaining an organized and accessible inventory. This versatility demonstrates the adaptability of lift tables to different operational needs across sectors.

Comparing Lift Tables for Home and Industrial Use

Lift tables offer a range of applications in both home and industrial settings. In home environments, they are particularly useful for tasks such as DIY projects, moving heavy items, or providing an ergonomic workspace in garages. They can be adjusted to suit the height of the task at hand, reducing strain during repetitive actions like assembling furniture or organizing garage space. This versatility makes lift tables a valuable addition to household tool collections.

In industrial environments, lift tables become indispensable due to their ability to handle high-volume workloads, which are common in places like loading docks, assembly lines, and warehouses. Selecting the right lift table involves ensuring that it meets safety regulations and operational needs, such as load capacity and height adjustment features. By integrating lift tables into these settings, businesses can enhance the efficiency of their operations, reduce worker fatigue, and ensure compliance with workplace safety standards. Lift tables are crucial tools that cater to both individual and enterprise-level demands efficiently.

Types of Lift Tables Available

Lift tables come in various forms, each suited to different operational needs. A primary distinction is between manual and electric lift tables. Manual lift tables are often praised for their simplicity and lower initial cost. They require physical effort to operate, typically using a hydraulic system, which makes them ideal for small-scale tasks or where power sources are limited. However, for larger or more complex tasks, electric lift tables are a superior option. They offer ease of use through motorized lifting mechanisms, reducing the risk of operator fatigue but generally come at a higher cost and require more maintenance due to their complex components.

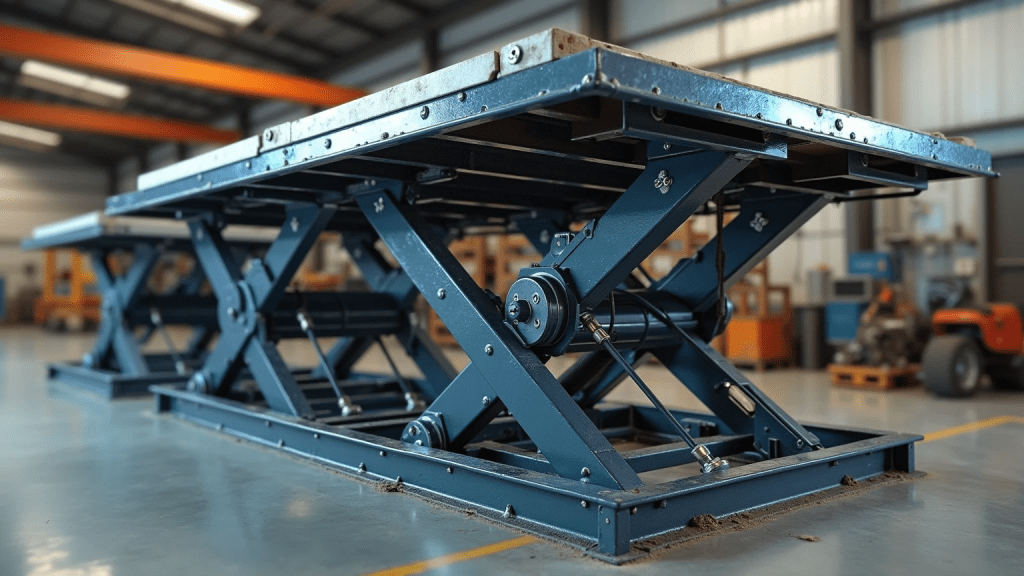

The design of a lift table can significantly affect its functionality and suitability for specific tasks. Different designs cater to various needs; fixed-height tables provide stability for routine tasks while adjustable height tables offer versatility for dynamic environments where the height of the work surface frequently alters. Additionally, specialized lift tables, such as scissor lift or tilt tables, provide unique capabilities for particular functions. Scissor lifts are popular for their vertical lifting action making them suitable for loading and unloading, while tilt tables are perfect for applications requiring angle adjustments. Selecting the right design involves assessing the specific requirements of your operations and determining which features will deliver the most efficiency and safety.

Choosing the Right Lift Table for Your Needs

Selecting the right lift table involves considering several critical factors to ensure optimal performance and safety. First and foremost, evaluate the load capacity required for your operations. It’s crucial that the lift table can handle the maximum weight of your materials safely. Next, consider the height range you need, ensuring it can adequately lift and lower to your specific requirements. Finally, think about the frequency of use; heavier-duty models are better suited for frequent usage as they can withstand wear and tear more effectively.

1. Load Capacity: Ensure the lift table supports the maximum weight you handle.

2. Height Range: Verify that the table reaches necessary heights for your tasks.

3. Frequency of Use: Choose robust models for higher operational demands.

Compatibility with existing equipment is another significant factor. The lift table must integrate smoothly with existing machinery to prevent disruptions. For example, if you use specific storage containers, choose a lift table that accommodates their size and shape. Seamless integration minimizes downtime and improves efficiency, allowing your operations to run smoothly without unnecessary adjustments or compatibility issues.

Conclusion: Maximizing the Benefits of Lift Tables

Thoughtful selection and proper usage of lift tables can significantly improve safety, productivity, and efficiency in both home and industrial settings. By choosing the right equipment tailored to your specific needs, you can enhance operational workflows and ensure a safer working environment. Employing these versatile tools effectively means investing in the long-term success and safety of your operations.

FAQ Section

What are lift tables used for?

Lift tables are used to safely elevate, lower, and position workloads, mainly to facilitate the handling of goods by adjusting them to a comfortable working height.

What are the benefits of using lift tables in the workplace?

Lift tables enhance ergonomics and safety by reducing physical strain, minimizing the risk of musculoskeletal injuries, and boosting productivity by streamlining material handling tasks.

How do I choose the right lift table for my needs?

Consider the load capacity, height range, and frequency of use. Ensure compatibility with existing equipment to prevent operational disruptions.

What are the different types of lift tables available?

Lift tables can be manual or electric. They also come in various designs, such as scissor lift and tilt tables, catering to different operational needs.

Can lift tables be used in home settings?

Yes, lift tables can be used for home tasks like DIY projects, moving heavy items, and creating ergonomic workspaces, making them a valuable addition to household tools.

留下评论