What Are Lockout-Tagout (LOTO) Locks?

Lockout-Tagout (LOTO) locks are critical safety devices used to isolate energy sources, preventing the accidental startup of machinery during maintenance and servicing. By utilizing these locks, companies can effectively manage hazardous energy, significantly reducing the risk of injuries associated with unexpected equipment activation. According to OSHA, implementing LOTO procedures is essential as it has dramatically decreased workplace incidents involving machines that require servicing.

The primary purpose of LOTO locks is to ensure worker safety by controlling hazardous energy. Data from OSHA highlights the effectiveness of these systems; for example, proper use of LOTO protocols can prevent thousands of workplace injuries annually, reinforcing their importance in industrial environments. These statistics underline the necessity of adhering to LOTO procedures to maintain a safe working environment.

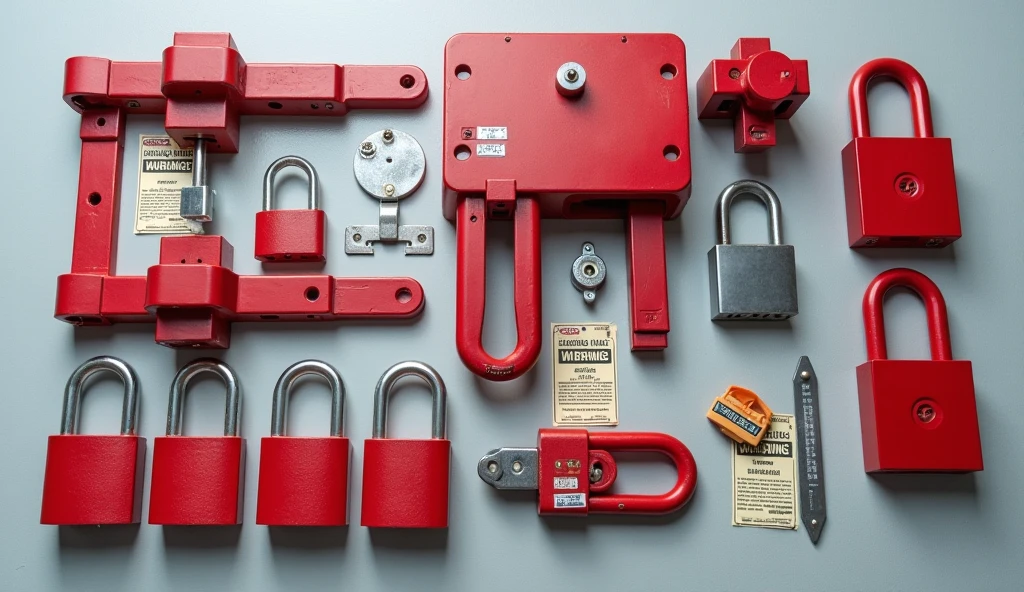

LOTO systems consist of various components, including mechanical locks, hasps, and tags, each serving different functions in safeguarding workers. Mechanical locks are used to physically secure energy isolation points, while hasps allow for multiple locks, ensuring comprehensive protection during group servicing tasks. Tags are essential for communicating the lockout status, indicating who applied the lock and when. These devices are crucial across different work environments, ensuring that energy sources remain controlled, and workers are not exposed to potential hazards.

The Importance of Lockout-Tagout for Safety

The Lockout-Tagout (LOTO) system is vital in preventing workplace accidents related to improper machine operation. According to the Occupational Safety and Health Administration (OSHA), failure to control hazardous energy accounts for nearly 10% of serious workplace incidents. A notable example is the tragic incident involving Mar-Jac Poultry, where the absence of proper safety measures led to severe consequences. Implementing LOTO effectively can significantly mitigate such risks by ensuring equipment is inoperable during maintenance, safeguarding workers from unexpected energization or startup.

Understanding hazardous energy sources is crucial for maintaining a safe working environment. These energy sources include electrical, mechanical, hydraulic, and pneumatic systems, each posing unique risks. For instance, electrical hazards can cause shocks or electrocution, while mechanical energy can result in amputations if machinery is not properly locked out. Hydraulic and pneumatic systems pose risks of high-pressure release, emphasizing the need for comprehensive safety protocols tailored to each energy type.

Implementing LOTO practices fosters a culture of safety within organizations, enhancing employee awareness and compliance with federal regulations. Such practices not only protect workers but also align with OSHA standards, which frequently cite violations related to machine guarding and hazardous energy control. By integrating LOTO procedures into the workplace, organizations promote a proactive approach to safety, ensuring all employees understand and adhere to these critical safety measures. This commitment ultimately reduces operational risks and enhances overall workplace safety.

Effectiveness of Lockout-Tagout Locks in Hazard Control

The effectiveness of Lockout-Tagout (LOTO) locks in hazard control is evident through various studies and industry reports. Statistics indicate that compliance with LOTO procedures is integral to decreasing workplace accidents. For instance, a report from the Occupational Safety and Health Administration (OSHA) highlights that proper LOTO implementations have led to a substantial reduction in the number of injuries related to machinery operation. This correlation demonstrates the key role LOTO plays in safeguarding the workplace by effectively managing hazardous energy sources.

Case studies from diverse industries further illustrate the success of LOTO practices. In manufacturing, for example, companies that have rigorously implemented LOTO procedures documented measurable safety improvements, such as a significant drop in workplace injuries. Similarly, in construction environments, LOTO has contributed to minimizing fatal incidents by ensuring machinery is securely disabled during maintenance. These real-world examples underline the critical impact of thorough LOTO practices in enhancing operational safety and preventing worker injuries.

Safety professionals across various sectors have consistently emphasized the value of LOTO in ensuring safe maintenance practices. Testimonials from organizations like the American Society of Safety Professionals (ASSP) endorse LOTO as an essential component of workplace safety. By fostering an environment where hazardous energy is systematically controlled, LOTO empowers employees to perform maintenance activities with confidence and adherence to safety standards. This commitment to safety not only protects workers but also reinforces compliance with regulatory requirements, thus cementing LOTO’s importance in hazard control.

Regulatory Standards Governing Lockout-Tagout Practices

The Occupational Safety and Health Administration (OSHA) establishes crucial regulatory standards that govern lockout-tagout (LOTO) practices to ensure workplace safety. The primary OSHA regulation for LOTO is 29 CFR 1910.147, which mandates that employers implement procedures to control hazardous energy during the maintenance and servicing of machines. Compliance with these regulations requires employers to develop and implement a comprehensive energy control program that includes training, equipment, and inspections.

Adhering to these standards is not optional but a legal requirement. Non-compliance can lead to severe penalties under both federal and state laws, including substantial fines that emphasize the importance of maintaining safety. A recent example includes Mar-Jac Poultry’s settlement with the Department of Labor, highlighting the costly consequences of safety violations. This case underscores the need for strict enforcement and adherence to these regulations to prevent workplace accidents and fatalities.

Over time, LOTO regulations have evolved to address emerging safety challenges and technological advancements, ensuring continuous improvement in workplace safety compliance. As industries and technologies change, so do the standards, ensuring that workplaces stay abreast of best practices for maintaining a safe environment. This evolving nature of regulations requires companies to stay informed and regularly update their safety protocols.

Best Practices for Implementing Lockout-Tagout Systems

Conducting comprehensive training and awareness programs for employees is crucial for successful lockout-tagout (LOTO) implementation. Effective training should cover key components such as understanding all types of hazardous energy, the necessity of LOTO procedures, and the roles and responsibilities of each team member. Regular training refreshers ensure that employees stay informed of the best practices and updates in safety protocols.

To create an effective LOTO procedure, start by identifying all potential energy sources within your operations. Notify all affected employees about the procedure and the equipment being serviced. Use proper devices to lock out equipment and implement a strict verification process to ensure that isolation is achieved. This systematic approach not only enhances safety but also ensures compliance with OSHA standards.

Furthermore, conducting ongoing audits and providing continual training refreshers can help keep safety at the forefront in workplaces. Regular audits help identify any lapses in adherence to LOTO procedures, while refresher courses ensure all employees are updated on any changes or advancements in safety protocols. Sustaining these practices minimizes risks associated with maintenance and promotes a culture of safety.

How to Choose Effective Lockout-Tagout Locks for Safety

Choosing effective lockout-tagout (LOTO) locks is crucial for maintaining safety standards in any facility. When selecting LOTO locks, consider key features such as durability, visibility, ease of use, and compatibility with various energy sources. These characteristics ensure that the locks are robust enough to prevent accidental release and are easily identifiable to everyone involved.

There are several common lockout devices, including padlocks, circuit breaker lockouts, and valve lockouts. Each has specific usage scenarios depending on the industry and equipment. For instance, padlocks are universally applicable across different machinery, while valve lockouts are more industry-specific, suitable for isolating energy in pipelines. It is essential for businesses to regularly review and evaluate the effectiveness of their current LOTO devices. This continuous assessment ensures that they not only comply with safety regulations but also enhance workplace safety by reducing potential hazards.

FAQ

What is the primary purpose of Lockout-Tagout (LOTO) locks?

The primary purpose of LOTO locks is to control hazardous energy and ensure worker safety during maintenance and servicing by preventing the accidental startup of machinery.

Why is implementing LOTO important for workplace safety?

Implementing LOTO is crucial for preventing workplace accidents related to improper machine operations, as it helps to control hazardous energy sources that account for serious workplace incidents.

What are some common types of energy sources considered in LOTO procedures?

Common types of energy sources include electrical, mechanical, hydraulic, and pneumatic systems, each posing unique risks requiring tailored safety protocols.

How does OSHA impact Lockout-Tagout practices?

OSHA sets regulatory standards under 29 CFR 1910.147, requiring employers to develop comprehensive energy control programs, ensuring strict compliance to enhance workplace safety.

留下评论