Understanding the Importance of Welding Screens in Safety

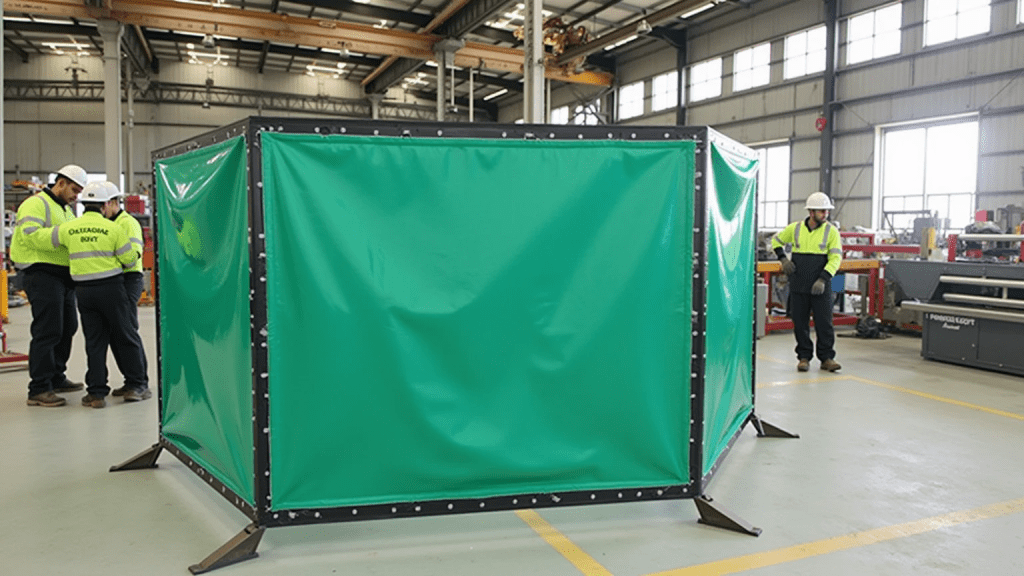

Welding screens serve as a critical protective barrier, safeguarding workers not just from sparks, but also from harmful UV rays and flying debris. These hazards pose significant risks to welders and nearby personnel, making welding screens indispensable in any welding environment. The use of welding screens helps mitigate these dangers by providing a physical shield that blocks out harmful light radiation and prevents debris from reaching vulnerable areas. This protective measure ensures that workers remain safe during the welding process, thereby reducing the incidence of injuries.

Moreover, the role of welding screens in containing and redirecting hazardous materials is essential for preventing serious injuries. By encapsulating the welding area, these screens effectively limit the exposure of dangerous materials to unprotected workers in the vicinity. This function is particularly vital because it helps maintain a safe workplace, ensuring that the potential for accidents and injuries is minimized. In environments where welding is a daily activity, the implementation of welding screens offers both practical and essential safety benefits, contributing to overall workplace safety standards.

Key Features of Effective Welding Screens

To ensure optimal safety and functionality, welding screens must be constructed from materials known for their durability and safety features. Common materials include vinyl and woven fabrics; each offering unique advantages. Vinyl is frequently chosen due to its affordability, flexibility, and ease of cleaning, making it suitable for dynamic work environments. Woven fabrics, while often more costly, provide enhanced strength and resistance to wear and tear, increasing their longevity in high-intensity welding settings. These materials are designed to withstand the harsh conditions of welding processes.

An effective welding screen also needs to maintain the right balance of visibility and light transmission. This involves allowing enough light to pass through for visibility without causing glare, which can lead to eye strain. Studies suggest that screens with appropriate coloring, such as bronze or green, can enhance visibility by minimizing glare while maintaining protective capabilities. This makes it safer and more comfortable for workers to monitor welding activities without compromising their vision or safety.

Moreover, welding screens must adhere to critical safety standards to ensure comprehensive protection. Standards such as ANSI and OSHA outline the necessary criteria for flame resistance and other protective features. These certifications are crucial, as they are developed by safety experts to minimize workplace hazards. Compliance ensures that a welding screen can effectively protect against harmful radiation and potential fire risks, aligning with industry best practices for safety in welding operations. Ensuring these certifications are met is a testament to the screen’s ability to provide a safe working environment.

Choosing the Best Welding Screen for Safety

Selecting the appropriate welding screen for safety is crucial to preventing workplace injuries. Critical factors to consider include the thickness, height, and portability of the screen. A thicker material often provides better protection against welding hazards, such as UV radiation and heat. However, the right thickness can vary depending on the specific welding process. Height is important to ensure adequate coverage, particularly in environments where multiple workers are present or where welding is conducted at various levels. Portability is another key consideration, especially for temporary setups or mobile work environments. Screens with enhanced mobility are preferred for jobs that require frequent relocation.

For specific welding applications, tailored recommendations can enhance safety and efficiency. In MIG welding, a robust screen that offers excellent clarity and visibility is ideal, allowing for precise monitoring of the weld. TIG welding might require a more transparent screen, promoting better observation while ensuring protection from harmful rays. Stick welding, known for producing more sparks and spatter, might benefit from screens with enhanced fire resistance and a stronger build. By selecting screens that best match these applications, workplaces can maximize safety while maintaining productivity.

The Role of Color in Welding Screens

The color of welding screens plays a critical role in safety and effectiveness. Understanding color codes is essential, as they denote the level of protection and visibility offered by the screen. Standard colors like dark green or yellow are commonly used, each offering specific benefits. Darker shades typically block more light and UV rays, providing greater protection, while lighter shades may enhance visibility in certain work environments.

Furthermore, the choice of color significantly impacts eye strain and visibility. Studies highlight that certain colors can reduce eye fatigue and improve overall visibility under various lighting conditions. For instance, green screens are often preferred as they can filter harmful radiations effectively while also reducing glare. This means the color of a welding screen isn’t just a matter of personal preference; it’s a crucial factor in maintaining visual comfort and ensuring safe working conditions for welders.

Compliance and Certification for Welding Screens

Compliance and certification play critical roles in ensuring the safety of welding screens. Key regulatory bodies like the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) set essential safety standards for welding equipment. Their guidelines ensure that welding screens provide adequate protection against hazards such as harmful UV radiation. Compliance with these standards is crucial in maintaining a safe work environment.

Certification is paramount in the welding industry because it significantly reduces the risk of injury. Certified welding screens adhere to stringent safety benchmarks and have been proven to offer superior protection compared to their non-certified counterparts. This assurance of safety not only protects workers but also helps in maintaining organizational standards and compliance, thereby minimizing potential liabilities.

Conclusion: The Best Welding Screen for Safety

In conclusion, the most effective welding screens for safety incorporate key features such as robust materials, UV protection, and flexibility in mobility within the workspace. These essential characteristics ensure maximum protection, reducing exposure to harmful radiation and preventing injuries. Looking forward, advancements in technology and materials, such as enhanced vinyl and smart sensor integration, could further revolutionize welding safety by offering smarter and more adaptable solutions.

FAQ

What is the primary purpose of a welding screen?

The primary purpose of a welding screen is to protect workers from sparks, harmful UV rays, and flying debris, ensuring their safety during the welding process.

What materials are commonly used for welding screens?

Common materials for welding screens include vinyl and woven fabrics, chosen for their durability, flexibility, and resistance to wear and tear.

Why is the color of welding screens important?

The color of welding screens is important as it affects protection levels and visibility, with certain colors reducing eye strain and filtering harmful radiation.

What safety certifications should welding screens have?

Welding screens should comply with safety standards set by regulatory bodies like OSHA and ANSI, ensuring protection against UV radiation, flame resistance, and other hazards.

留下评论