Understanding Lift Table Maintenance

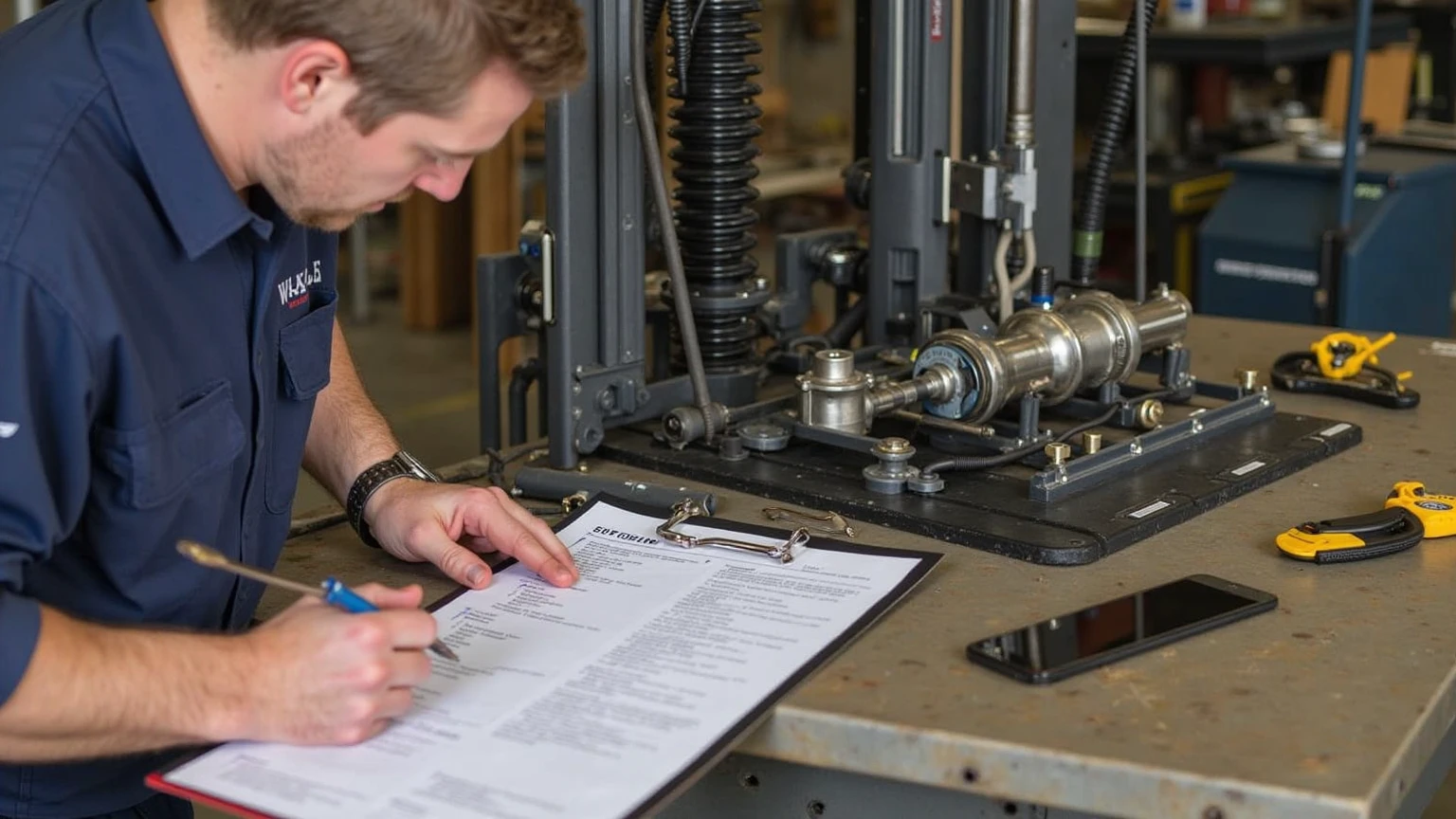

Regular maintenance is essential for ensuring the longevity and optimal performance of lift tables. According to industry experts, consistent upkeep not only prevents costly repairs but also minimizes downtime, thereby maintaining productivity levels. Overlooking routine checks can lead to issues that might disrupt operations and escalate repair costs significantly.

To maintain lift tables efficiently, some key practices should be followed. Firstly, inspect hydraulic systems regularly to ensure they are functioning smoothly and free from leaks. Safety mechanisms should be tested to guarantee they are in proper working order, enhancing the safety of users and materials. Additionally, cleaning moving parts can eliminate debris accumulation, ensuring that all components interact seamlessly. Implementing these maintenance strategies will ensure that lift tables serve their purpose effectively and withstand daily operational demands.

Safety Protocols for Using Lift Tables

Ensuring the safe use of lift tables involves adhering to essential safety guidelines. These include respecting load limits to prevent strain on the machinery and using proper lifting techniques to avoid injury. It’s also crucial to keep the area surrounding the lift table free from obstructions. This preventive measure minimizes the risk of accidents caused by tripping or unintended contact with moving parts. According to safety standards, these practices not only protect users but also enhance the longevity of the equipment.

Training and education play a pivotal role in safe lift table operation. Users must receive detailed instruction on the proper use of this equipment, including awareness of potential hazards such as pinch points and the importance of regular equipment checks. Training should emphasize identifying signs of wear or malfunction, as well as procedures for reporting maintenance issues. Providing comprehensive education ensures that operators are well-prepared to manage the equipment confidently and maintain a safe working environment.

Best Table Lifts for Home and Office

Choosing the best table lifts for home and office environments involves considering several key features. Essential aspects include adjustable height settings, weight capacity, and overall stability, which cater to various user needs. Flexibility in height means that a table lift can serve multiple purposes, accommodating both tall and short users, while a sturdy design ensures safety and durability during use. Particularly in busy environments, stability can prevent accidental tipping and ensure seamless operation.

Reviewing popular table lift models can be highly beneficial in selecting the right product. Comparative analyses often rely on customer feedback and expert reviews, helping identify which models stand out. Consideration of both positive and negative reviews can grant a comprehensive understanding of each model’s performance. Models recommended by ergonomic specialists, for instance, often come highly rated for their reliability and user-friendly design. These details can be pivotal in making an informed purchase.

Top recommendations for table lifts usually focus on renowned brands with a history of reliability and safety. Brand names that consistently receive praise in reviews can be trusted to provide quality manufacturing and prolonged service life. Ergonomists frequently suggest brands that integrate user-friendly designs with robust construction, ensuring that the products can withstand regular use across different settings. These factors ensure that the investment not only meets functional requirements but also offers efficiency and longevity.

Troubleshooting Common Issues with Lift Tables

Identifying and troubleshooting common issues with lift tables are essential for maintaining efficient operations. Mechanical problems can often be diagnosed by checking hydraulic fluid levels, examining electrical connections, and assessing the functionality of control buttons. For example, low hydraulic fluid may cause sluggish movement, while a loose electrical connection could result in unresponsive controls. Proper maintenance and regular checks can help preempt these issues before they escalate.

A step-by-step troubleshooting guide can be invaluable for resolving common lift table problems. Begin with simple solutions like ensuring that control buttons are securely connected and operational. For uneven lifting, verify that the load is evenly distributed and check the lift table for any worn or damaged components. If unusual noises are encountered during operation, inspect the hydraulic or pneumatic systems for leaks or blockages, and make necessary adjustments. By following these troubleshooting steps, users can maintain the optimal performance of their lift tables and ensure safe operation.

Enhancing Ergonomics with Lift Tables

Adjustable height is a key feature of lift tables, significantly contributing to ergonomic benefits by accommodating various user heights. This adaptability promotes greater comfort and minimizes physical strain, making these tables highly conducive to supportive work environments. For office workers, ergonomic enhancements can lead to improved posture, a reduced risk of developing musculoskeletal disorders, and increased productivity. Studies from health organizations have shown that adapting workstations to fit individual needs not only boosts efficiency but also enhances overall well-being.

Troubleshooting Common Issues with Lift Tables

Identifying mechanical problems with lift tables often involves a few systematic checks, such as reviewing hydraulic fluid levels, examining electrical connections, and ensuring the control buttons function correctly. To assist in resolving common issues like unresponsive controls, uneven lifting, and unusual noises, a step-by-step troubleshooting guide can be invaluable. This guide should lay out simple solutions, enabling users to address and fix these minor hiccups and ensure the smooth operation of lift tables in various applications.

Frequently Asked Questions

Why is regular maintenance important for lift tables?

Regular maintenance prevents costly repairs and minimizes downtime, ensuring optimal performance and longevity of lift tables.

How can I ensure the safe use of lift tables?

Adhere to safety guidelines by respecting load limits, using proper lifting techniques, and keeping the area free from obstructions.

What should I look for when choosing table lifts for home and office?

Consider adjustable height settings, weight capacity, stability, and customer reviews to ensure you choose the right model for your needs.

What are common troubleshooting steps for lift tables?

Common troubleshooting involves checking hydraulic fluid levels, electrical connections, and ensuring control buttons are functional.

留下评论