Understanding Electric Drum Pumps

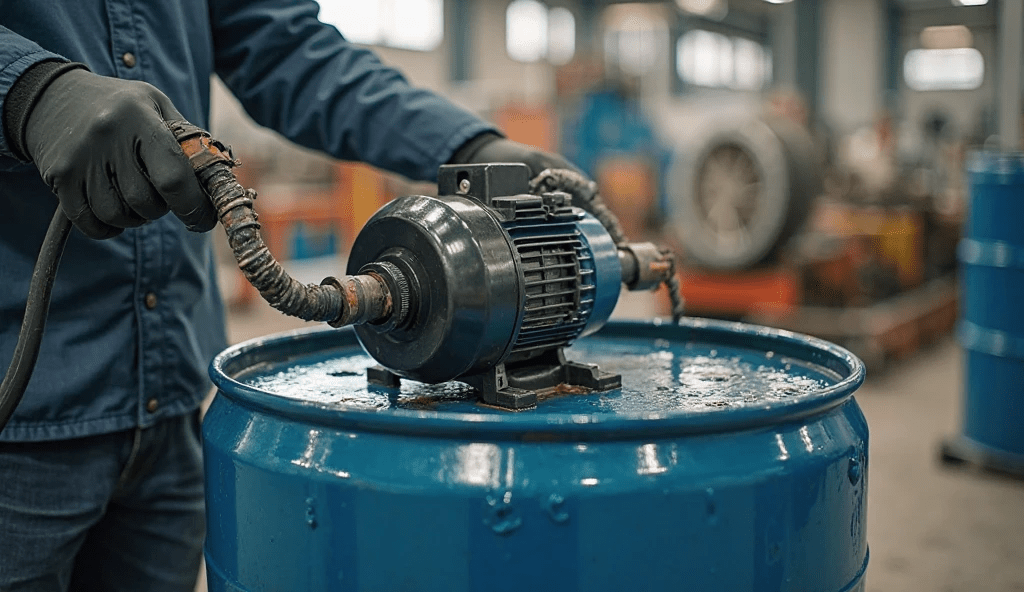

Electric drum pumps are specialized tools designed to transfer liquids from drums or containers efficiently. They utilize an electric motor, making them suitable for a wide range of fluids, from water to hazardous chemicals. These pumps provide an effective solution for managing the fluid transfer process, minimizing the effort and time required when compared to manual methods. Their application extends across various industries such as manufacturing, chemical processing, and more, where the handling and transport of both hazardous and non-hazardous substances are essential.

One of the defining features of electric drum pumps is their versatility. These pumps are available in different designs, including submersible and non-submersible types. Submersible pumps are ideal for applications where the pump needs to be placed directly within the drum, whereas non-submersible pumps are used externally. This variety allows users to select the most appropriate pump type based on specific applications and the nature of the liquids being transferred, ensuring optimal efficiency and safety.

Furthermore, the efficiency and ease of use of electric drum pumps make them a preferred choice in various sectors. These pumps significantly reduce the manual labor required to transfer liquids, thus improving productivity. Their consistent performance facilitates smoother operations and enhances workplace safety by minimizing spillage and exposure risks. With advancements in technology, the reliability and precision of electric drum pumps continue to improve, cementing their role as indispensable tools in industrial liquid handling applications.

Types of Electric Drum Pumps

Electric Dirty Water Pumps

Electric dirty water pumps are specially designed to handle wastewater and liquids with solid particles, making them indispensable in construction and landscaping industries. These pumps are built with robust materials to endure corrosive environments and often feature advanced filtration systems that prevent clogging. Equipped to manage challenging conditions, these pumps ensure reliable performance even in demanding settings.

Grease Pump Electric

Grease pump electric models are engineered to efficiently manage and transfer thick fluids like grease and oil, which are commonly used in automotive and industrial applications. These pumps are equipped with built-in delivery systems that guarantee a controlled and efficient dispensing of lubricants, ensuring that machinery remains well-lubricated and operational. This design not only enhances the productivity of maintenance tasks but also reduces the time required for lubricating equipment.

Electric Water Pump for Liquid Transfer

Electric water pumps for liquid transfer are versatile solutions widely used for moving clear water and other low-viscosity fluids in both residential and industrial settings. They offer high flow rates, ensuring efficient liquid transfer across different applications. Additionally, these pumps can be customized with various hoses and fittings, allowing them to meet specific application needs effectively.

Factors to Consider When Choosing an Electric Drum Pump

Pump Capacity and Flow Rate

Understanding the pump capacity and flow rate is crucial for ensuring that the selected pump can handle your operational demands effectively. These parameters determine the volume of liquid that can be moved within a specific time frame, which helps in avoiding operational bottlenecks. Typically, flow rates are measured in gallons per minute (GPM) or liters per minute (LPM), and opting for a pump with adjustable settings can greatly enhance flexibility, allowing for better control over the pumping process.

Compatibility with Different Liquids

Not all electric drum pumps can handle every type of liquid, hence it is essential to consider compatibility with the viscosity, temperature, and chemical properties of the substances being pumped. This is especially vital if the liquids are hazardous, as using the wrong pump can significantly reduce efficiency or lead to equipment failure. Therefore, careful selection of a compatible pump is necessary to ensure both safety and optimal performance.

Power Source: 12V Diesel Electric Fuel Pump vs. Jet Pump 220V

The power source of an electric drum pump, such as a 12V diesel electric fuel pump or a jet pump 220V, can significantly influence its suitability for various applications. A 12V pump is ideal for remote work sites due to its portability, making it a convenient choice for tasks requiring mobility. Conversely, a 220V pump typically offers a higher power output, making it well-suited for stationary installations where consistent electrical supply is available. Choosing between these options depends primarily on the specific requirements of the application, including available power sources and site conditions.

Applications of Electric Drum Pumps

Industrial Use

Electric drum pumps are extensively utilized in industrial settings, where they play a vital role in transferring chemicals, oils, and wastewater. These pumps enhance operational efficiency by providing a reliable and seamless liquid transfer process. Their rugged design enables them to withstand the harsh environments found in manufacturing facilities, refineries, and waste management organizations, making them an essential tool for maintaining productivity and safety in these sectors.

Agricultural Use

In the agricultural sector, electric drum pumps are indispensable for transferring fertilizers, pesticides, and irrigation water. Their application leads to enhanced productivity and promotes sustainable agricultural practices by optimizing resource use. The versatility of these pumps in handling a wide variety of liquids makes them invaluable for modern farming operations, helping farmers manage their daily tasks with greater efficiency and reliability.

Residential Use

For residential applications, electric drum pumps serve a variety of purposes, such as transferring water from drums to gardens or for cleaning equipment. Their versatility and ease of use make them a practical choice for everyday tasks around the home. Families with gardening or aquatic hobbies particularly benefit from the efficiency and convenience these pumps provide, streamlining chores and aiding in the maintenance of their outdoor spaces.

Maintenance and Safety Tips

Regular Cleaning and Inspection

Regular maintenance, including cleaning and inspection of electric drum pumps, is essential to ensure their long-term reliability and performance. Cleaning the pumps after each use helps prevent clogs and contamination, which can significantly affect efficiency. Furthermore, routine inspections help identify wear and tear that could compromise the pump’s operation, allowing for timely repairs and preventing potentially costly downtime. By following these practices, users can extend the lifespan of their equipment and ensure consistent performance.

Safety Precautions During Operation

When operating electric drum pumps, it is crucial to observe safety precautions to prevent accidents and injuries. Always wear protective gear, such as gloves and goggles, and adhere strictly to the manufacturer’s operating instructions to minimize risks. Additionally, understanding the hazards associated with the specific liquids being handled, especially when dealing with hazardous substances, can further enhance safety. Awareness and preparedness are key components in safely managing operations involving these powerful devices.

Troubleshooting Common Issues

Familiarizing oneself with common troubleshooting steps for electric drum pumps can be invaluable in maintaining operational efficiency. Issues like low flow rate, unusual noises, or overheating can arise despite careful handling. Addressing these problems promptly through simple diagnostic steps can minimize downtime. For instance, checking for clogs, ensuring proper power supply, or inspecting seals and gaskets can often resolve many common issues quickly, allowing operations to continue smoothly.

FAQ

What are electric drum pumps used for?

Electric drum pumps are used to transfer liquids efficiently from drums or containers, ideal for both hazardous and non-hazardous substances across various industries such as manufacturing and agriculture.

Are electric drum pumps easy to maintain?

Yes, regular cleaning and inspection can ensure long-term reliability and prevent clogs and contamination.

Can I use an electric drum pump for all types of liquids?

Not all pumps can handle every liquid type. It’s crucial to ensure compatibility with the liquid’s viscosity, temperature, and chemical properties.

What power source options are available for electric drum pumps?

Common options include 12V diesel electric fuel pumps for portability and jet pump 220V for higher power output, suitable for stationary uses.

留下评论