Types of Steel Strapping and Their Applications

Stainless Steel Strapping: Corrosion Resistance & Durability

Stainless steel strapping is renowned for its exceptional resistance to rust and corrosion, making it ideal for challenging environments such as outdoor and marine applications. This type of strapping can withstand extreme temperatures, enhancing its durability across various industrial settings. Studies show that stainless steel outperforms other materials in terms of longevity, often lasting decades even in harsh environments. This resilience makes it the preferred choice for securing heavy goods and equipment that must endure prolonged exposure to the elements, despite its lack of elasticity.

Galvanized Steel Strapping: Cost-Effective Protection

Galvanized steel strapping undergoes a protective zinc coating process that effectively prevents rust, making it a cost-effective alternative for many applications. This type of strapping is commonly utilized in the packaging and shipping industries, where budget constraints are a priority. Evidence shows that galvanized options provide a viable alternative to stainless steel without significantly compromising on strength. Its primary advantage lies in its ability to deliver reliable performance at a lower cost, making it a preferred choice for businesses seeking budget-friendly yet durable solutions.

Painted/Organic Coated Steel: Customization & Versatility

Painted or organic coated steel strapping offers flexibility for businesses looking to personalize their strapping for branding and aesthetic purposes. These coatings not only allow customization but also add a protective layer that enhances the strapping’s versatility in various environments. Research indicates that such coatings can improve both the performance and longevity of the strapping, making them suitable for applications where appearance and durability are essential. This adaptability makes painted or organic coated steel an attractive option for industries needing both function and style.

Steel vs. Polyester vs. Polypropylene Strapping

Strength Comparison: When Steel Outperforms Alternatives

Steel strapping provides superior strength compared to polyester and polypropylene, especially in heavy-duty applications. It is renowned for its ability to withstand greater loads without bending or breaking, making it indispensable in industrial environments. The tensile strength of steel strapping can exceed 800 pounds per inch. This remarkable strength makes it the preferred choice for securing heavy and sharp-edged loads that require additional firmness. Studies consistently show that steel strapping maintains its tension over long periods, an essential quality for ensuring the safety of goods during prolonged storage or transportation.

Environmental Factors: Corrosion Resistance and UV Stability

Steel strapping stands out for its exceptional corrosion resistance, particularly in challenging environments. This attribute gives it an edge over polyester and polypropylene, making it ideal for outdoor applications where exposure to elements is inevitable. Testing has shown that steel strapping maintains its integrity under significant UV exposure, which guarantees its performance in various climates. This UV stability, alongside its robustness against moisture and temperature fluctuation, ensures consistent reliability, minimizing risks associated with environmental degradation of packaging materials.

Cost Analysis: Long-Term Value of Steel Strapping

Although the initial investment in steel strapping is often higher, its durability and longevity offer a better long-term value compared to alternatives like polyester and polypropylene. Cost studies indicate that opting for steel leads to savings on replacements and reduces downtime, which can accumulate significantly over time. Companies can optimize their return on investment by choosing steel strapping for applications involving demanding load conditions. While steel might seem pricier upfront, its resilience and minimal need for ongoing maintenance often prove more economical in the long run.

Essential Tools for Steel Strapping Systems

Pusher Bar Tensioners for Tight Seals

Pusher bar tensioners are indispensable when it comes to ensuring the proper tension of steel strapping, which is crucial for achieving tight and secure seals. These tools apply the necessary force to prevent strapping from loosening, minimizing the risk of strap failure during the transportation of heavy loads. Industry experts have noted that using pusher bar tensioners enhances the stability of secured loads, making them a recommended choice for businesses that prioritize secure transportation.

Heavy-Duty Sealers and Combination Tools

Heavy-duty sealers are specifically designed to join steel crimp seals effectively, providing robust adhesion that stands up to the rigors of transport. For versatility and increased operational efficiency, combination tools that integrate both sealing and tensioning functions in a single device are highly valued. User reviews often highlight these tools for their ability to speed up packaging processes, making them an essential component in heavy-duty industrial applications where time and efficiency are critical.

Safety Equipment for Handling Steel Straps

When handling steel straps, safety gloves and eye protection are essential to prevent injuries from sharp edges and high tension. Proper training in using safety gear is vital, as it significantly reduces the incidence of workplace accidents. According to data from the Occupational Safety and Health Administration (OSHA), facilities that invest in comprehensive safety training experience lower incident rates. By prioritizing employee safety, companies not only comply with safety regulations but also foster a safer, more productive work environment.

Key Features to Evaluate in Steel Strapping

Tensile Strength Requirements by Load Type

Understanding the tensile strength requirements is crucial for selecting the right steel strapping for your load. Different types of loads demand varying tensile strengths; for instance, heavy machinery often requires high tensile strength for secure transportation. Consulting engineering tables can assist in determining the correct strap for specific applications, ensuring both safety and effectiveness.

Coating Options for Specific Environments

The choice of coating for steel strapping significantly affects its performance, especially in corrosive or humid environments. Evaluating environmental conditions is essential to decide whether galvanized, painted, or stainless steel options are most suitable. Most product literature provides guidelines that help identify the appropriate coatings based on different application scenarios.

Width and Thickness Guidelines

Selecting the correct width and thickness for steel strapping is imperative for securing packages effectively. Industry standards often dictate these parameters to ensure safety and reliability. Comparative studies have shown that appropriately chosen dimensions enhance overall load management, reducing the risk of damage during transport.

Industry Standards and Trusted Manufacturers

Certifications to Look For (ASTM, ISO)

When choosing steel strapping, certifications such as ASTM and ISO are essential indicators of quality and reliability. These standards ensure that products have undergone rigorous testing and adhere to high-quality metrics. Reports suggest that utilizing certified products can significantly improve performance, particularly in heavy-duty applications where durability is critical. By assuring compliance with these standards, manufacturers provide assurance of the product’s safety and effectiveness in diverse industrial settings.

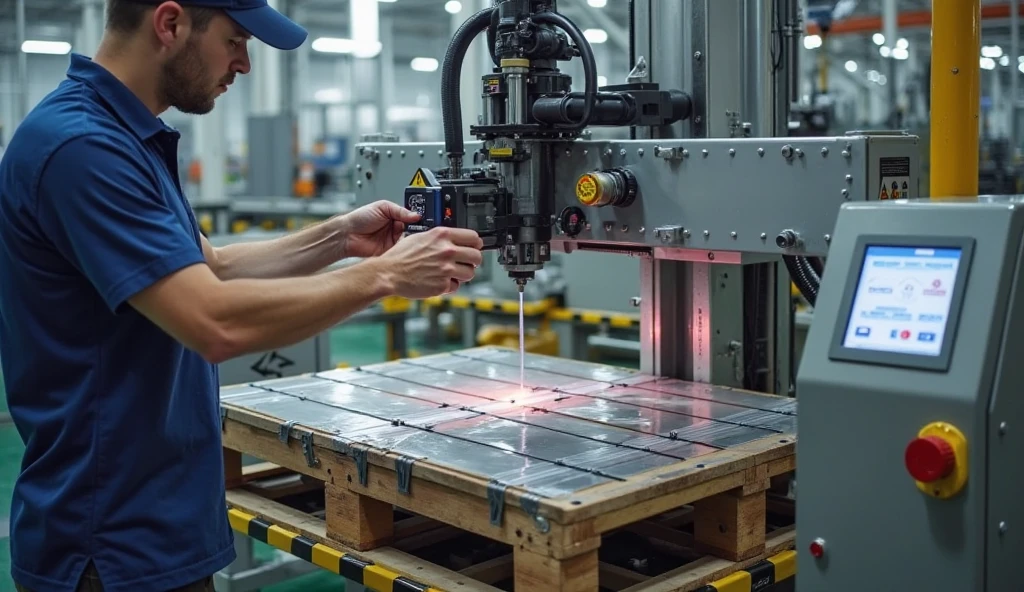

Innovations in Steel Strapping Technology

Recent innovations in steel strapping technology have transformed packaging processes, notably through automated strapping machines. These advancements aim to reduce manual labor while ensuring enhanced quality of seals and strap application. Case studies demonstrate that companies integrating these technologies are benefiting from substantial reductions in operational costs and improving overall efficiency. Such innovations are crucial, not only for streamlining operations but also for maintaining competitive advantage in the market.

Sustainability Practices Among Leading Brands

Increasingly, manufacturers are incorporating sustainability practices into their processes, focusing on recyclable materials and minimizing waste. These initiatives not only reflect an ethical commitment to environmental stewardship but also significantly influence procurement decisions. Research indicates that brands prioritizing sustainable production tend to outperform their competitors, establishing a valuable reputation among eco-conscious buyers and contributing to long-term success.

FAQ

What are the main types of steel strapping?

The main types of steel strapping are stainless steel, galvanized steel, and painted or organic coated steel.

Why is stainless steel strapping preferred in marine environments?

Stainless steel strapping is preferred because of its exceptional resistance to rust and corrosion, making it ideal for challenging and wet environments.

How does galvanized steel strapping offer cost-effective protection?

Galvanized steel strapping has a protective zinc coating that prevents rust, offering reliable performance and durability at a lower cost compared to stainless steel.

Why is steel strapping stronger than polyester or polypropylene?

Steel strapping provides superior strength due to its ability to withstand greater loads without bending or breaking, especially in industrial applications.

What certifications should I look for when purchasing steel strapping?

Look for certifications such as ASTM and ISO, which indicate quality and reliability after rigorous testing.

留下评论